Applications

Pipe ramming with the steel giant TERRA-HAMMER

The steel pipe rams of TERRA are one of the most fastest and strongest rams you can find in the world market. With its enourmous ramming force and the low air requirement the Swiss engineers have proven their talent in the art of engineering. With the steel pipe rams of TERRA you can ram steel pipes from 150 mm (6“) up to 3000 mm (120“).

Heavy main piston – 3 years of warranty (industry leading)

The heavy main pistons (strikers) produce the unusual high impact and ramming energy. The main piston weighs up to 60 % of the machine. Even the largest main pistons with a weight of 1.5 tonnes are produced from one single piece. Therefore there are no critical joints. Due to the heavy main piston the ram has an enormous ramming force. The impulse is transfered where it is needed – in the head! This is possible through the hollow head design. TERRA offers a warranty of 3 years for all main pistons.

Smart hollow head design

The TERRA-HAMMER is not afraid of any comparison to conventional rams due to TERRA’s tremendous power and enormous speed. If you compare the main pistons of TERRA to other conventional main pistons, you can see, that the TERRA main pistons are longer. The ram itselfe remains shorter but stronger at the same time. This is only possible because TERRA has invented the hollow head design. The impulse is transfered where it is needed – in the head. Thanks to the acceleration ports in the main housing the main piston can be moved with low air consumption.

Horizontal application

Steel pipes up to Ø 3’000 mm are rammed horizontally through the ground. The ram sits behind the steel pipe. Depending on ground conditions and steel pipe diameter drive lengths up to 120 m are possible.

Vertical application

The steel pipe rams of TERRA can also be used vertical. You can ram bollards into a lake with your TERRA ram.

Pipe roofing

The TERRA-ram can also be used in tunnel constructions. It rams several steel pipes parallel to produce a roof.

HDD assist

When pulling in long steel pipes with HDD drill rigs, the TERRA ram gives dynamic assistance at the rear of the steel pipe. This leads to higher productivity and longer drilling lengths.

HDD casing

When a HDD drill takes several months there is the risk, that the entry of the drill collapses. In such a case it is useful to ram a steel pipe 30 ‐ 50 m (100 ft) as a protection pipe into the ground.

HDD rescue

When a HDD drill is jammed, the TERRA ram helps to rescue the rods.

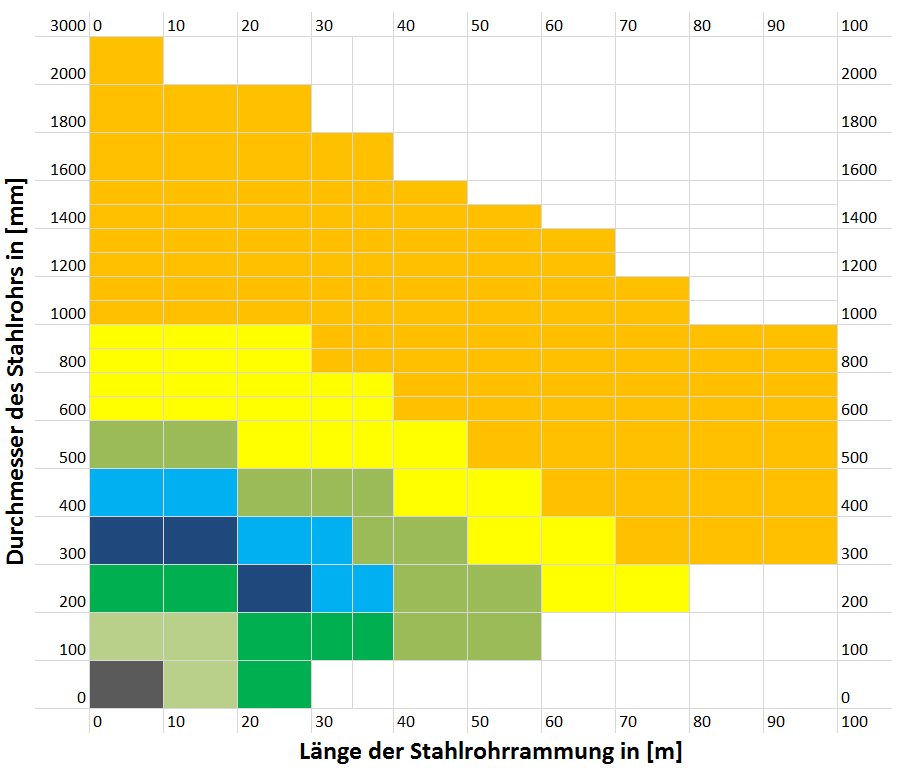

Ramming diagram

The size selection of the TERRA‐Ram depends on the diameter of the steel pipe, also the total length of the ramming job. The chart below can be used to select the most suitable size of TERRA‐Ram.

This chart can be used if ramming through medium strength ground. When ramming through much softer or harder ground a smaller or larger TERRA-Ram may be required. The above diagram is valid only for medium strength ground. TERRA cannot be held liable for any unsuccessful ramming job which was assumed possible based on the chart above, it is offered as a guide only.

Technical Data, metric

| TERRA-HAMMER | Diameter ø mm | Length m | Weight kg | Frequency 1/min | Consumption m3/min | Pressure bar | Expanders ø mm |

|---|---|---|---|---|---|---|---|

|

T = TERRA-HAMMER with fused on earth displacement head TU = TERRA-HAMMER with interchangeable head adapters TR = TERRA-RAM, for steel pipe ramming and pipe bursting (berstlining) S = TERRA-HAMMER Version S, with quick reverse (1/4 turn of the air hose) F = TERRA-HAMMER Version F, with remote control reverse S/F = TERRA-HAMMER, available in Version S and Version F K = TERRA-HAMMER Version K, not glued, can be serviced without heating SK = TERRA-HAMMER Version S + Version K KOK-LD = TERRA-HAMMER with traceable KOK-LD adapter Technical specifications can be changed without previous notice. |

|||||||

| TR 200mini |

200 mm

|

0.90 m

|

112 kg

|

550 /min

|

4.0 m3/min

|

6-7 bar

|

–

|

| TR 220 |

220 mm

|

1.60 m

|

315 kg

|

320 /min

|

7.0 m3/min

|

6-7 bar

|

–

|

| TR 360 |

360 mm

|

1.75 m

|

663 kg

|

280 /min

|

12 m3/min

|

6-7 bar

|

–

|

| TR 565 |

565 mm

|

2.30 m

|

2’535 kg

|

195 /min

|

34 m3/min

|

6-7 bar

|

–

|

Technical Data, us

| TERRA-HAMMER | Diameter ø inch | Length inch | Weight lbs | Frequency b/min | Consumption cfm | Pressure psi | Expanders ø inch |

|---|---|---|---|---|---|---|---|

|

T = TERRA-HAMMER with fused on earth displacement head TU = TERRA-HAMMER with interchangeable head adapters TR = TERRA-RAM, for steel pipe ramming and pipe bursting (berstlining) S = TERRA-HAMMER Version S, with quick reverse (1/4 turn of the air hose) F = TERRA-HAMMER Version F, with remote control reverse S/F = TERRA-HAMMER, available in Version S and Version F K = TERRA-HAMMER Version K, not glued, can be serviced without heating SK = TERRA-HAMMER Version S + Version K KOK-LD = TERRA-HAMMER with traceable KOK-LD adapter Technical specifications can be changed without previous notice. |

|||||||

| TR 200mini |

7.9″

|

35″

|

247 lbs

|

550 /min

|

140 cfm

|

100 psi

|

–

|

| TR 220 |

8.7″

|

63″

|

694 lbs

|

320 /min

|

245 cfm

|

100 psi

|

–

|

| TR 360 |

14″

|

68″

|

1,460 lbs

|

280 /min

|

420 cfm

|

100 psi

|

–

|

| TR 565 |

26″

|

91″

|

5,588 lbs

|

195 /min

|

1,190 cfm

|

100 psi

|

–

|

Kontakty

Vedúci divízie cestnej mechanizácie

Ing. Otokar Macháček

Technické poradenstvo Dynapac a Terra

Diagnostický technik

Tel. kontakt: +421 948 332 182

Email: otokar.machacek@jamalsk.sk

Náhradné diely

Jakub Mihalik

Technické poradenstvo

Tel. kontakt: +421 903 721 664

Email: jamalsk@jamalsk.sk