HDD class: 4 – 6 tons

75 HP strong HATZ Diesel engine – HDD drill rig DJ 10

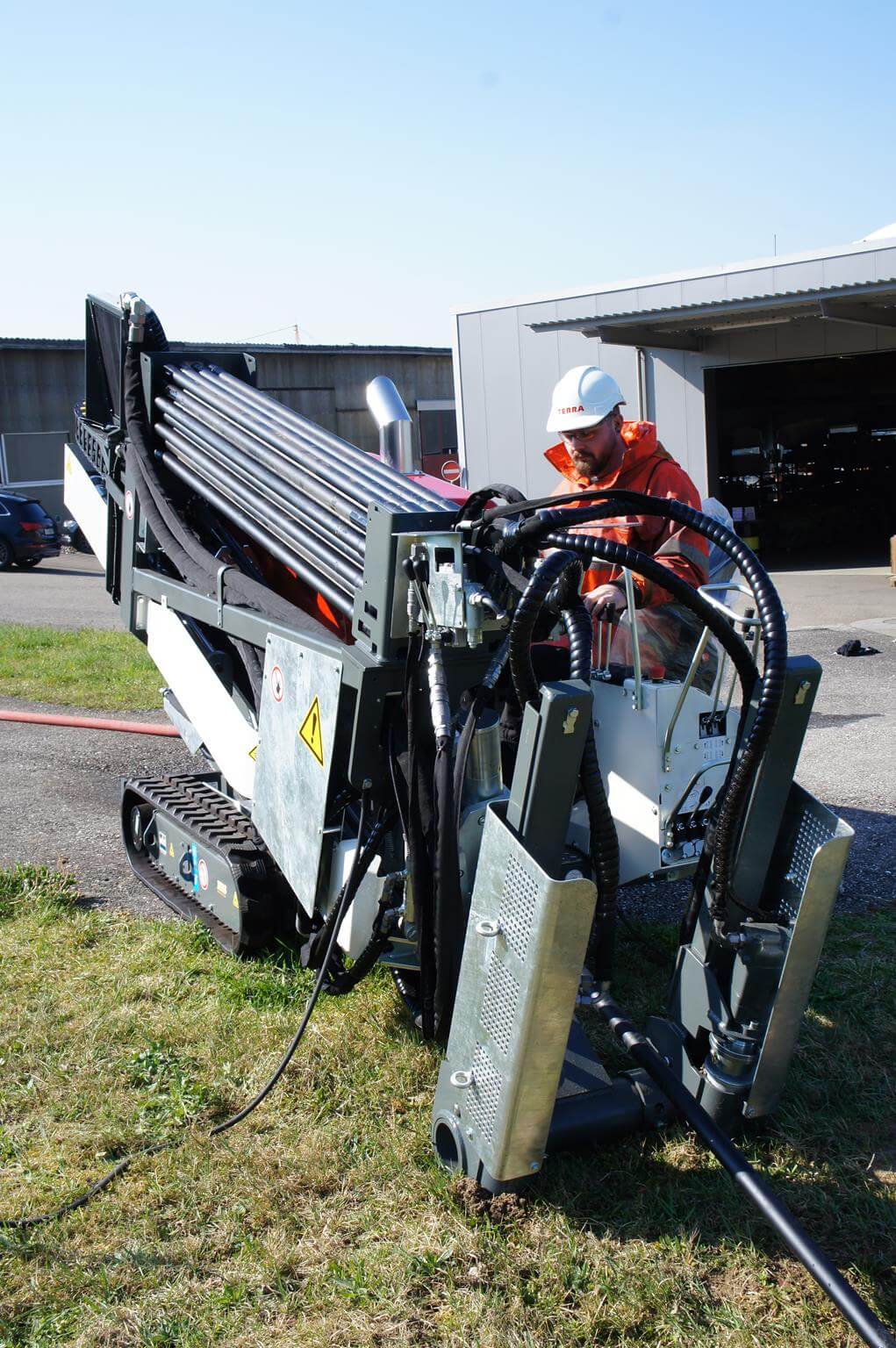

The HDD drill rig DJ 10 combines compact design with a powerful inside. This horizontal directional drill rig has a torque of 1,800 Nm (1,325 ft.lbs) @ 180 rpm on the drill rods. With a thrust and pullback force of 42 kN (4.2 tonnes) you can drill lengths up to 90 m (300 ft) and bore channels up to Ø 260 mm (10”).

It is the ideal machine for new pipe laying over short distances and small diameters such as fiber optic cables or house connections.

The small footprint and the reduced noise level at the operator’s ear make the DJ 10 user friendly and sustainable. The fast set up time and the increased movability helps you to operate your machine also in urban areas or family‘s backyard.

1800 Nm @ 180 rpm – fast and strong

The TERRA-JET DJ 10 has 25 % more ROTATION power than any other HDD machine in the 4 tons (9,150 lbs) class. It provides a torque of 1,800 Nm (1,325 ft.lbs) at 180 rpm. Both maximum figures can be reached simultaneously. This solves even difficult drilling problems.

With an increased drilling volume of 100 ltr/min contractors can face various challenging ground conditions. The DJ 10 is standardly equipped with 45 ltr/min.

FMC Pump on board (95 ltr/min – 26 gpm)

With an increased drilling volume of 95 ltr/min (26 gpm) contractors can face various challenging ground conditions.

Entry angle up to 67 %

Standard the entry angle (inclination of the drill ramp) is 35 % (19°).

Then the rubber crawler and the front ground plate touch the surface. In case of narrow space within cities the drill head should reach the horizontal drilling depth in a short distance. Then the drill ramp must be adjusted at a higher angle. The drill ramp of the TERRA-JET DJ 10 can be adjusted up to 67 % (34°). The optional rear support plate lifts the rubber crawler for 0.24 m (9.5”) and adjusts the HDD machine horizontal.

Ergonomic operator’s station

The control platform is clearly arranged. Even large drillmasters have enough space. THRUST and ROTATION are controlled with one lever with the right hand. All other functions as breaking apart or drilling fluid are controlled with the left hand. The instrument panel is also clearly arranged.

Double cylinder drive („DIRECT RAM“) – free of losses

THRUST and BACKREAMING of the driving saddle happens by a direct double cylinder drive („DIRECT RAM“). This is free of losses, robust and powerful. This new idea from TERRA allows maximum drilling and backreaming forces. Even at slow speeds, even with a short drilling ramp. The double cylinder operates in both directions with 42 kN (4.2 tons, 9’150 lbs). In the quick gear the driving saddle reaches 46 m/min (150 ft/min). The driving saddle is supported by roles on top, at the bottom and sidewise.

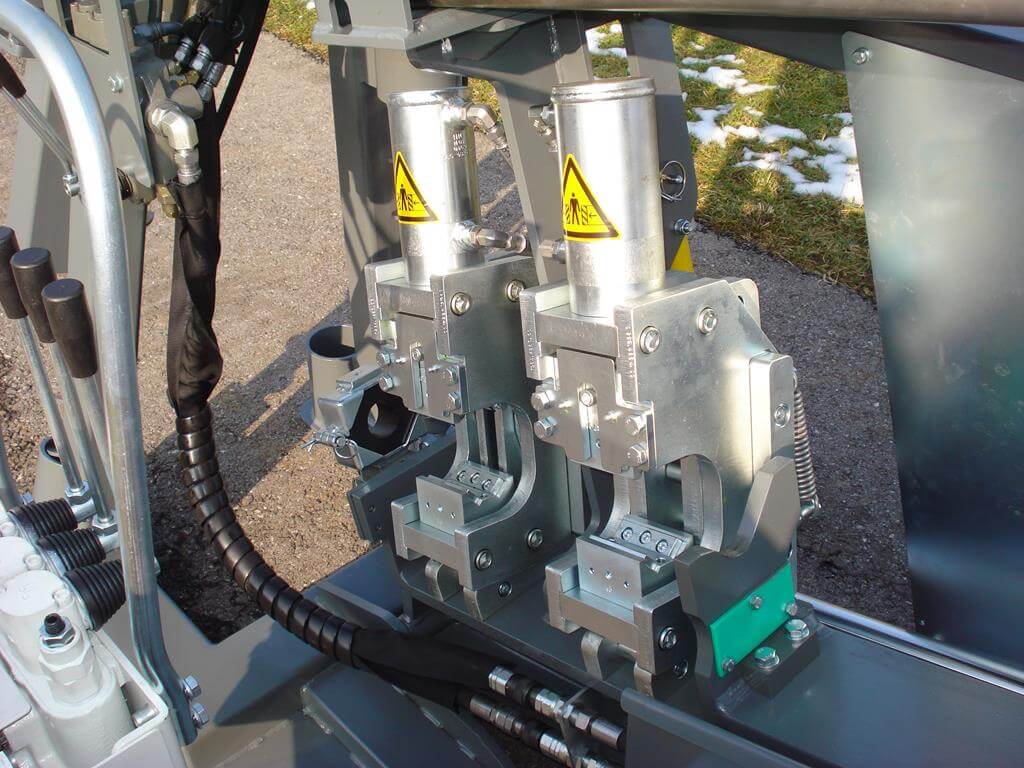

Break-Apart System

The break-apart system allows the hydraulic break-apart of the drill rod threads. The vertical positioning allows an easy view. Break-apart torque: 4’500 Nm (3’300 ft.lbs), clamping force 100 kN (10 tons/22’000 lbs)

Anchoring system

The hydraulic anchoring system works with two independent pillars. The anchoring system has hard-metal teeth. They even drill through asphalt and gravel. Each pillar can be adjusted individually in any angle. If there are pipes in the ground, the anchoring system can even be adjusted sidewise.

Service friendly

The S-Series is designed to be extremely service friendly and reliable. All hydraulic components are easily accessible for servicing. The engine cover is made of glass fibre reinforced plastic (GRP) and can be lifted up to 45°, supported by gas-filled struts. They can also be lifted off completely allowing the best access to all components. The electric components are assembled in the central control panel inside of the cabin with easy access.

| Technical Data | |||

|---|---|---|---|

|

* Depending on ground conditions ** Depending on drill rod size Technical specifications can be changed without previous notice. |

|||

| Pullback force |

42 kN (4.2 t)

|

9,150 lbs

|

|

| Thrust force |

42 kN (4.2 t)

|

9,150 lbs

|

|

| Engine power |

Hatz 55 kW (75 PS)

|

Hatz 55 kW (75 HP)

|

|

| Torque, max. |

1’800 Nm @ 180 U/min

|

1,325 ft.lbs @ 180 rpm

|

|

| Drill rod rotation speed, max. |

180 U/min

|

180 rpm

|

|

| Drilling fluid volume |

95 l/min

|

26gpm

|

|

| Drilling fluid volume, optional |

45 l/min

|

12 gpm

|

|

| Drilling fluid pressure, max. |

55 bar

|

800 psi

|

|

| drilling speed – quick gear |

46 m/min

|

150 ft/min

|

|

| drilling speed – at full load |

16 m/min

|

50 ft/min

|

|

| pullback speed – quick gear |

46 m/min

|

150 ft/min

|

|

| pullback speed – at full load |

16 m/min

|

50 ft/min

|

|

| ø of the pilot bore |

60 – 110 mm

|

2.5” – 4”

|

|

| Entry angle, min. |

18° (33 %)

|

18° (33 %)

|

|

| Entry angle, max |

27° (50 %)

|

27° (50 %)

|

|

| Backreaming diameter, max.* |

ø 260 mm

|

ø 10″

|

|

| Maximum drilling length* |

90 m

|

300 ft

|

|

| Drill rods, length |

2.0 m

|

6.6 ft

|

|

| Drill rod, diameter |

50/42 mm

|

2″ / 1.7 “

|

|

| Driving speed |

2.2 km/h

|

1.1 miles/h

|

|

| Bending radius, min.** |

20 m

|

65 ft

|

|

| noise emission at operator’s ear – without cabin |

85 dB(A)

|

85 dB(A)

|

|

| Guaranteed sound power level Lwa |

104 dB(A)

|

104 dB(A)

|

|

| Dimensions L x W x H (working position) |

4.05 x 1.50 x 2.10 m

|

13.4 x 5.0 x 6.9 ft

|

|

| Dimensions L x W x H (driving position) |

4.25 x 1.20 x 2.25 m

|

14.0 x 4.0 x 8.1 ft

|

|

| weight incl. drill rods |

3.4 t

|

7,500 lbs

|

|

| Weight without drill rods |

2.75 t

|

6,070 lbs

|

|

Kontakty

Vedúci divízie cestnej mechanizácie

Ing. Otokar Macháček

Technické poradenstvo Dynapac a Terra

Diagnostický technik

Tel. kontakt: +421 948 332 182

Email: otokar.machacek@jamalsk.sk

Náhradné diely

Jakub Mihalik

Technické poradenstvo

Tel. kontakt: +421 903 721 664

Email: jamalsk@jamalsk.sk