HDD class: 18 – 20 tons

TERRA-JET DJ 40 – 175 HP strong engine

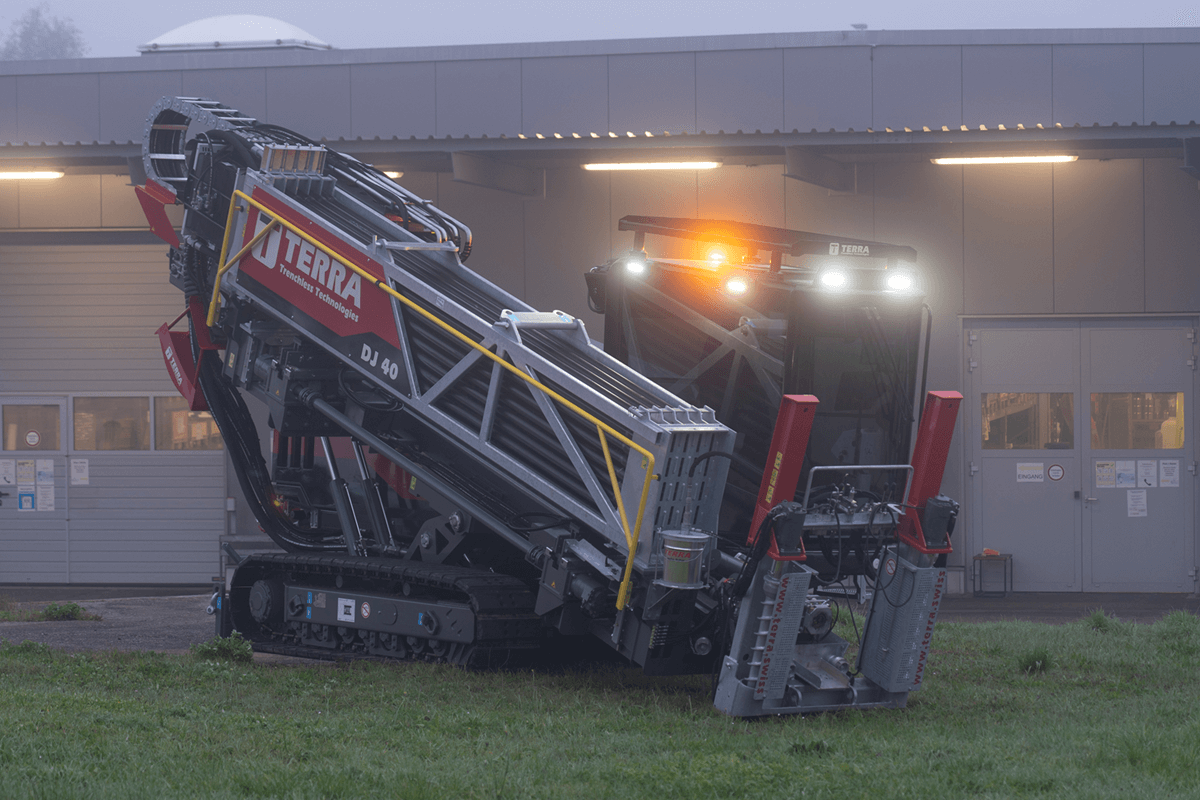

Built from our customer’s feedback and input, the DJ 40 is a modern evolution of productive and enhanced horizontal directional drill units designed by TERRA.

Powered by a proven 175 HP strong PERKINS Diesel engine (Euro Stage 5) the TERRA-JET DJ 40 offers up to 18 tons of thrust and pullback force, 8.000 Nm of rotational torque and a maximum spindle speed of 255 rpm.

A combination you need for outstanding productivity on big installation jobs, to work more efficiently with less downti

Cabin with tinted glas and free-hands device

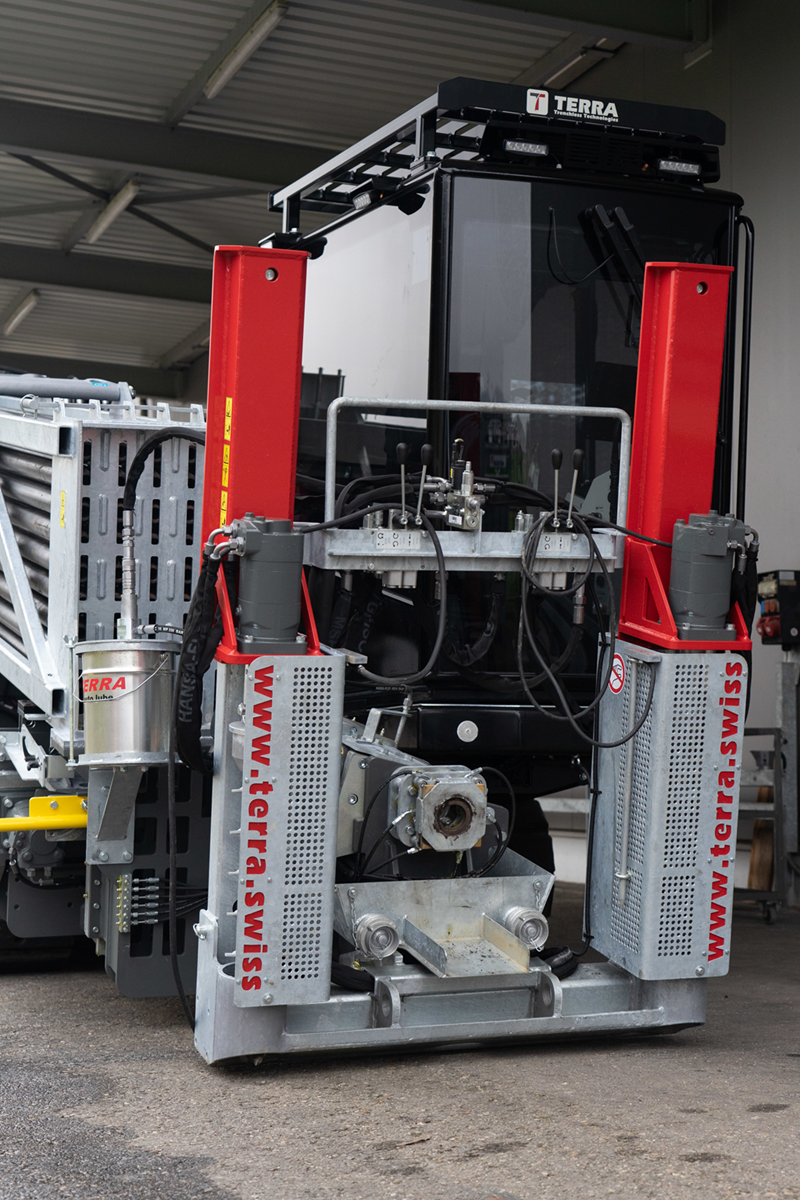

The cabin of the DJ 40 offers the best-in-class visibility of drilling operations with a clear view to critical vision points, including ground entrance, break-apart system and rear connection.

The DJ 40 has a fully enclosed cabin which offers premium operator comfort such as an integrated free-hands device, climate control and a small fridge. The increased legroom keeps drillers comfortable during long hours on a job.

Swing-out-cabin

The cabine of the DJ 40 can be moved hydraulically from 0°‐ 45°, even if the operator is in the cab. This industry-leading cab places the operator at a precise angle, providing an enhanced view of drilling operations.

Easy access and servicefriendly design

The hood of the DJ 40 can be lifted completely for easy access for machine maintenance and serviceability. The hood is insulated from inside, which leads to a reduced noise level at the operators ear.

Oscillating drill ramp

The patented, oscillating drilling ramp has two cylinders with two different rotation points. The drill ramp can move up and down, but also forward and backwards. This allows entry angles of 19% – 38% (11° – 20°). The crawler always remains on the ground for full stability.

Drill rod magazine with add-a-pipe design

The DJ 40 has 50 drill rods on board, each 4.57 m (15 ft) long. This adds up to a total drill length of 230 m (755 ft). For higher productivity you refill the magazine with a unique add-a-pipe system or you just exchange the empty drill rod magazine against a full one. The bending radius of the premium drill rods is 34 m.

Bentonite collecting tray

The bentonite is collected over a three-stepped collecting tray system. Your machine stays clean which leads to a higher safety of your jobsite.

Unique operating concept

Intelligent drilling assistant systems like the thrust control, carve mode and the drill speed control make the drilling more efficient and easier. The operator can relax, the machine does the work. The electronical drilling and backreaming system ADBSe adjustes the pulling speed within milliseconds.

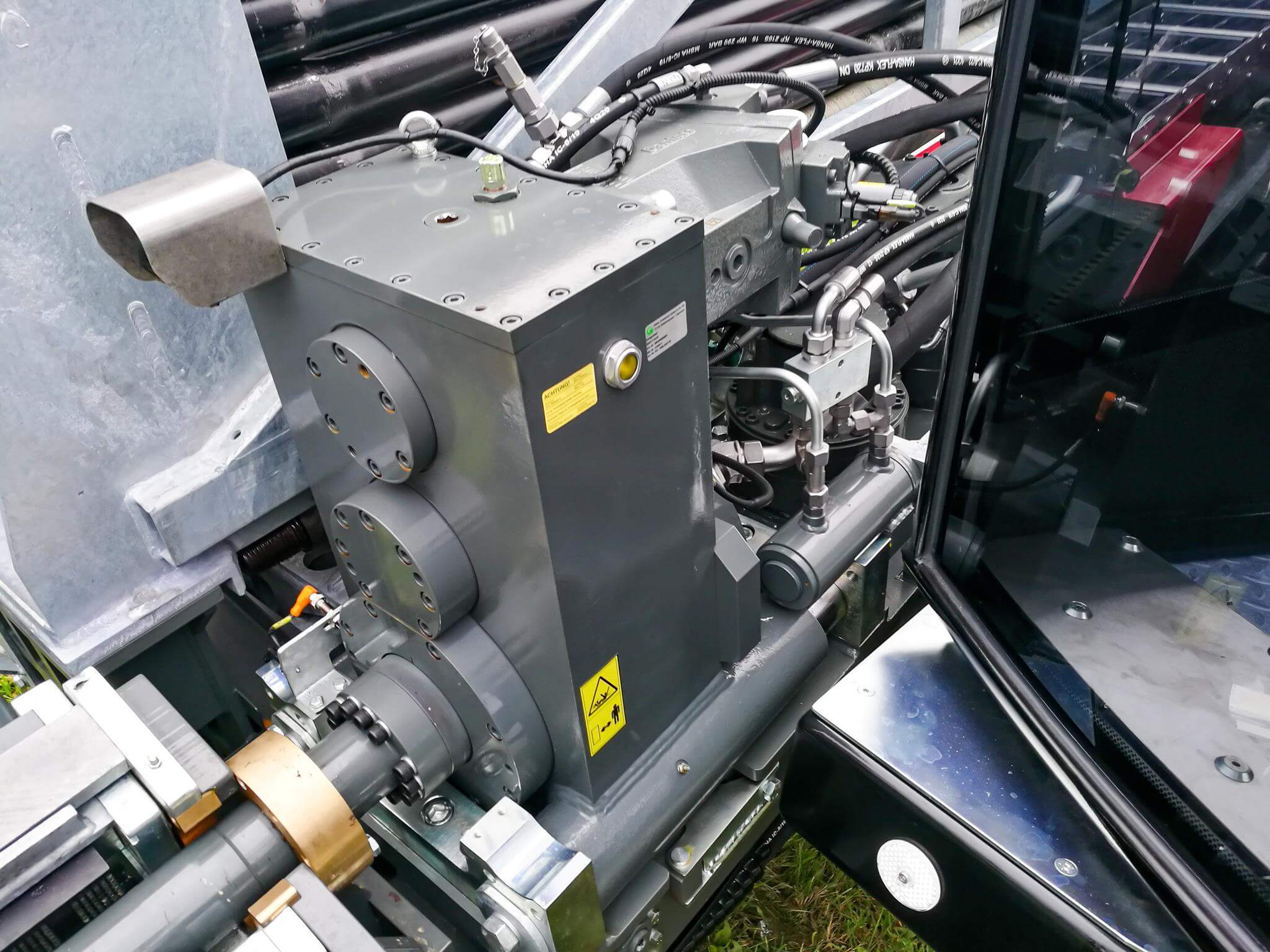

AutoTork (patent)

The bent axis variable displacement motor of the driving saddle creates the high torque. The torque of 8‘000 Nm and the drill rod rotation speed of 255 rpm can be adjusted manually. In total there are 11 gears. The operator regulates them easily on the display of the cabin (AutoTork).

New telemetric system

With a new telemetric system, you as a customer can keep track of the status of your machine. All necessary information such as location of your drill rig, information regarding the drill status or upcoming service is shown in real time. The data is saved in a cloud. The data can be conveniently accessed and operated with a smartphone or a tablet.

Wireless remote control

The installation and driving of the DJ 40 is done by a wireless remote control. This leads to a faster job site set-up.

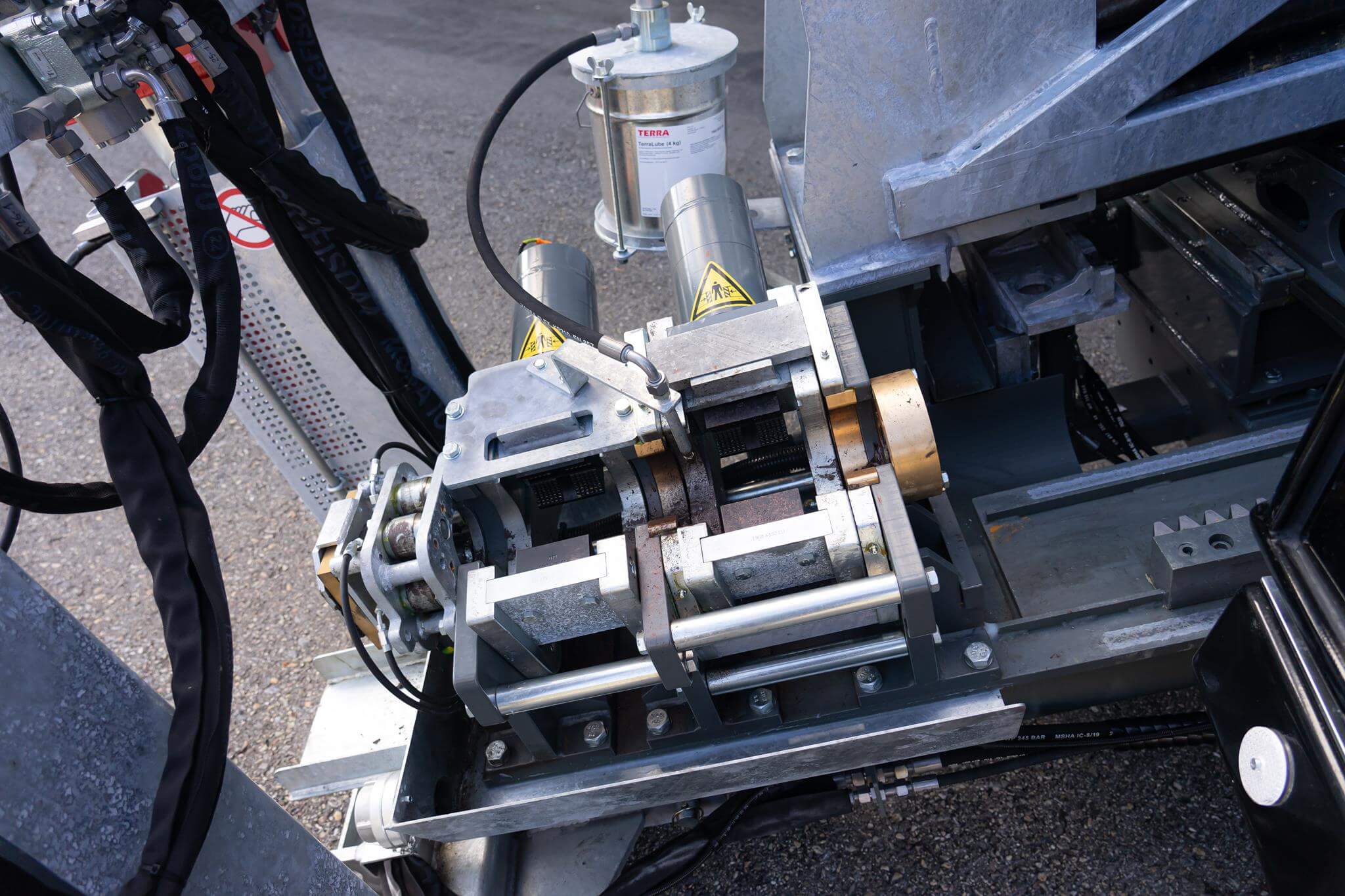

Onboard fluid pump

The onboard, enclosed 400 l/min strong fluid pump leads to productive drilling at greater distances. The flow rate can be adjusted simultaneously with thrust, pullback and rotation. A sensor measures the flow rate continuously. If the tank is empty, the sensor closes the valve which leads to a long lifetime of the seals inside the fluid pump.

Cable guided drilling (wireline)

The DJ 40 is pre-equipped for cable guided drilling. The break-apart system is big enough to lay drill heads of wireline-systems into it.

| Technical Data | |||

|---|---|---|---|

|

* Depending on ground conditions |

|||

| Pullback force |

181 kN (18 t)

|

40.000 lbs

|

|

| Thrust force |

181 kN (18 t)

|

40.000 lbs

|

|

| Engine power |

Perkins 129 kW (175 PS)

|

Perkins 129 kW (175 HP)

|

|

| Torque, max. |

8’000 Nm

|

5.900 ft.lbs

|

|

| Drill rod rotation speed, max. |

255 U/min

|

255 rpm

|

|

| Drilling fluid volume |

400 l/min

|

135 gpm

|

|

| Drilling fluid volume, optional |

510 l/min

|

135 gpm

|

|

| Drilling fluid pressure, max. |

70 bar

|

1.015 psi

|

|

| drilling speed – quick gear |

44 m/min

|

145 ft/min

|

|

| ø of the pilot bore |

140 – 170 mm

|

5.5” – 6.7”

|

|

| Entry angle, min. |

11° (19 %)

|

11° (19 %)

|

|

| Entry angle, max |

20° (38 %)

|

20° (38 %)

|

|

| Backreaming diameter, max.* |

ø 800 mm

|

ø 30”

|

|

| Maximum drilling length* |

400 m

|

1250 ft

|

|

| Drill rods, length |

4.57 m

|

15 ft

|

|

| Drill rod, diameter |

79/76 mm

|

3.1” / 3.0”

|

|

| Driving speed |

3.2 km/h

|

2.3 miles/h

|

|

| Bending radius, min.** |

34 m

|

110 ft

|

|

| noise emission at operator’s ear – without cabin |

79 dB(A)

|

79 dB(A)

|

|

| Guaranteed sound power level Lwa |

104 dB(A)

|

104 dB(A

|

|

| Dimensions L x W x H (working position) |

8.14 x 2.18 x 3.68 m

|

26,7 x 7,2 x 12,1 ft

|

|

| Dimensions L x W x H (driving position) |

8.44 x 2.18 x 2.88 m

|

27,6 x 7,2 x 9,4 ft

|

|

| Dimensions L x W x H (transportation position) |

8.23 x 2.18 x 2.84 m

|

26,0 x 7,2 x 6,5 ft

|

|

| weight incl. drill rods |

16.5 t

|

36.000 lbs

|

|

| Weight without drill rods |

13.0 t

|

29.800 lbs

|

|

Kontakty

Vedúci servisu

Dezider Baláž

Technické poradentsvo Putzmeister a Dynapac

Diagnostický technik

Tel. kontakt: +421 910 910 451

Email: servis@jamalsk.sk

Vedúci divízie cestnej mechanizácie

Ing. Otokar Macháček

Technické poradenstvo Dynapac a Terra

Diagnostický technik

Tel. kontakt: +421 948 332 182

Email: otokar.machacek@jamalsk.sk

Náhradné diely

Jakub Mihalik

Technické poradenstvo

Tel. kontakt: +421 903 721 664

Email: jamalsk@jamalsk.sk