2000 – 4000 l

MS 700 – Highest efficiency and performance

The MS 700 fluid mixing system was designed to provide highest performance and efficiency at low costs. Powered by a proven HONDA mixing pump it offers up to 700 ltr/min (200 gpm) of drilling fluid. It is equipped with a 2000 ltr (530 gal) tank for maximum fluid capacity. Optionally TERRA even offers a second tank for higher fluid capacity. The MS 700 supports horizontal directional drilling systems of all sizes.

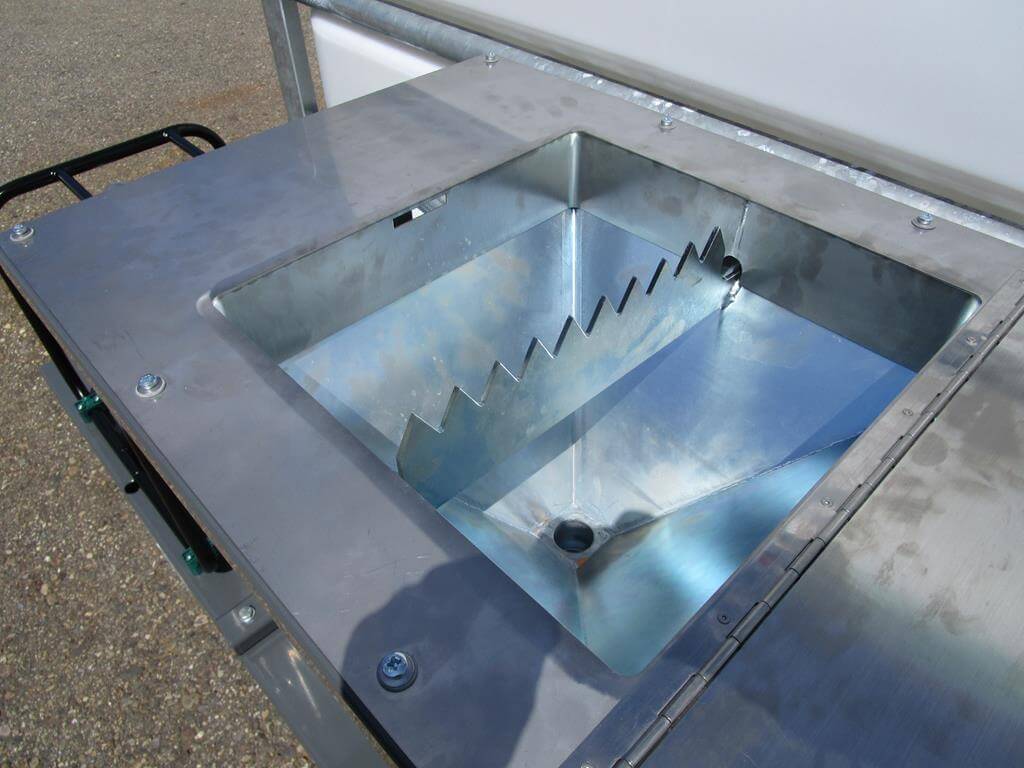

High speed injector

The high speed injector is equipped with a big funnel for 25 kg (55 lbs) of bentonite. Next to it is a cleaning pipe with hose. It cleans the injector if it gets stuck.

Funnel with underpressure (Venturi system)

The big funnel with cutting knife makes your HDD live easier on the jobsite. The cutting knife in the funnel opens the bentonite bags. A 25 kg (55 lbs) bag of bentonite can be placed besides the funnel. Due to the venturi pipe there is an underpressure in the whole system. The bentonite is sucked into the mixing unit which provides a reliable mixing.

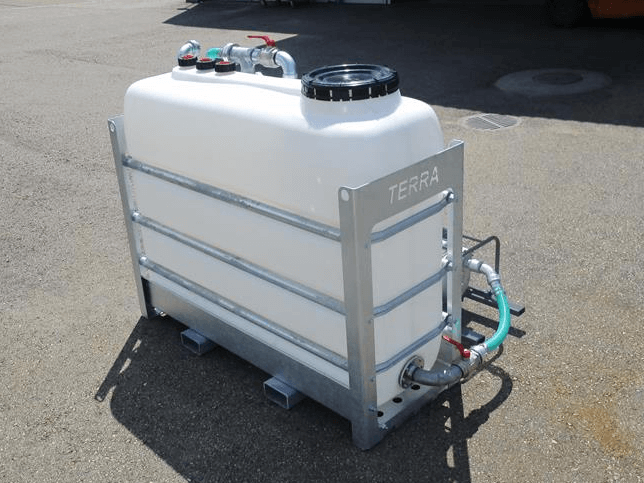

2000 ltr (550 gal) or 2×2000 ltr (2×550 gal) tank with bottom flushing

The MS 700 is standardly equipped with a 2000 ltr (550 gal) tank. TERRA also offers a second tank for a higher drilling fluid capacity. The tank has integrated a special bottom flushing system. It prevents that the bentonite settles down at the bottom. It is fed from the top and can be opened with an user friendly regulation valve.

Compact design

The MS 700 has a very compact design. It can be installed easily on a truck without taking too much space. The mixing station can be lifted with a fork lift or with a crane or excavator at the four lifting eyes. If lifted, the tank must always be empty.

| Technical data | |||

|---|---|---|---|

|

Technical specifications can be changed without previous notice. |

|||

| Power, mixing pump |

5 PS (4 kW)

|

5 HP (4 kW)

|

|

| Fuel |

Benzin

|

Petrol

|

|

| Pump discharge rate |

700 l/min

|

185 gpm

|

|

| Fluid pressure |

26 m (2.6 bar)

|

377 psi

|

|

| Flow rate to boring unit |

25 m (2.5 bar)

|

360 psi

|

|

| Typical mixing time per 1’000 ltr of water |

5 min

|

5 min

|

|

| Distance to boring unit |

60 m

|

200 ft

|

|

| Mixing hopper capacity |

25 kg

|

55 lbs

|

|

| Drilling fluid tank capacity |

2000 / 4000 l

|

530 / 1060 gal

|

|

| Dimensions with one tank L x W x H |

2300 x 1400 x 1950 mm

|

90 x 55 x 77 in

|

|

| Dimensions with two tanks L x W x H |

2300 x 2200 x 1950 mm

|

90 x 87 x 77 in

|

|

| Weight with one tank (empty) |

780 kg

|

1720 lbs

|

|

| Weight with two tanks (empty) |

1430 kg

|

3150 lbs

|

|

Kontakty

Vedúci servisu

Dezider Baláž

Technické poradentsvo Putzmeister a Dynapac

Diagnostický technik

Tel. kontakt: +421 910 910 451

Email: servis@jamalsk.sk

Vedúci divízie cestnej mechanizácie

Ing. Otokar Macháček

Technické poradenstvo Dynapac a Terra

Diagnostický technik

Tel. kontakt: +421 948 332 182

Email: otokar.machacek@jamalsk.sk

Náhradné diely

Jakub Mihalik

Technické poradenstvo

Tel. kontakt: +421 903 721 664

Email: jamalsk@jamalsk.sk