HDD class: 8 – 10 tons, pit launch machine

Pit launch drilling with the DJ 18 PIT

The TERRA-PIT DJ 18 is the most powerful and productive HDD pit launch machine that is available on the world market. Powered by a proven 75 HP HATZ Diesel engine the DJ 18 PIT offers up to 8 tons of thrust and pullback force and 3.000 Nm of torque. With its 95 ltr/min of drilling volume and a maximum drilling pressure of 70 bar you can backream up to 420 mm over lengths of 150 (depending on ground conditions).

The TERRA-PIT DJ 18 can be pit or surface launched. This HDD system has a modular design. Its main components are the pit frame, the hydraulic power pack and the mixing+pumping station.

With its 2 separated hydraulic circuits for thrust and rotation, the DJ 18 PIT can operate simultaneously at maximum torque and maximum thrust or pullback force. The hydro-chain-drive has the highest efficiency rate, low wear and is dirt resistant. Due to the movable break-apart-system.

Available as a short and long version

The machine is available as a short version (L=2.0 m) and a long version (L=2.5 m). With a width of only 0.9 m it fits perfectly in any compact pit. The small footprint and the reduced noise level at the operator’s ear make the TERRA-PIT DJ 18L user friendly and sustainable. The fast set up time and the increased movability helps you to operate your machine also in urban area. The machine can be equipped with an optional rubber crawler.

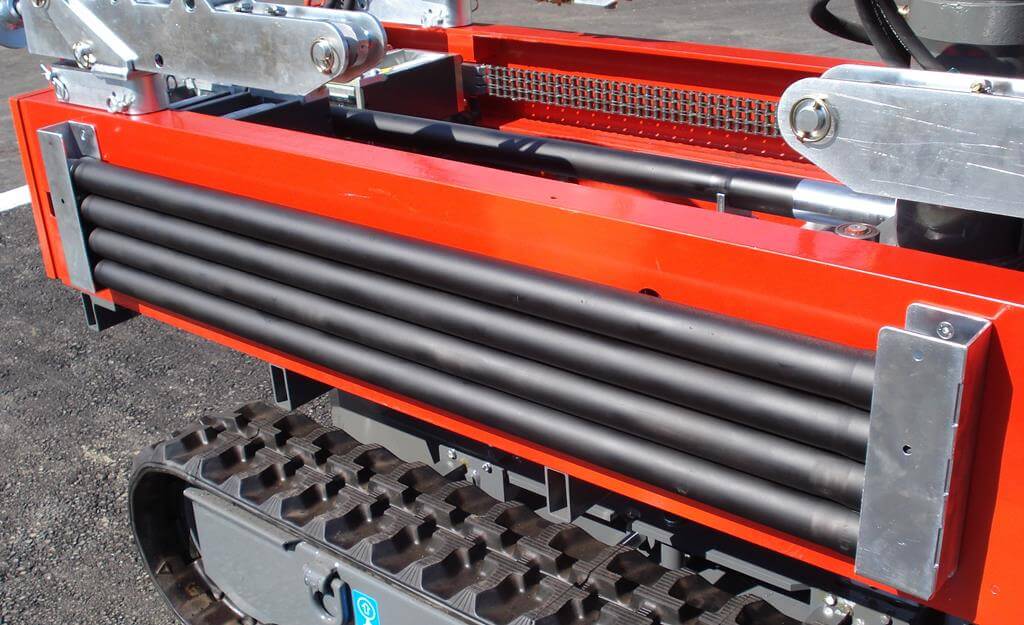

Hydro chain drive

Thrust and pullback of the driving saddle is done by a hydro-chain-drive. The two static chains are mounted on the launching cradle. The two engines move along the chain. This is powerful and sustainable. The hydro-chain-drive operates in both directions with 8 tons. Highest efficiency can be reached.

Pulling of the pipe right into the pit

The break‐apart-system can be moved backwards. Now the backreamer and the new pipe can be pulled into the working pit. All tools can be disassembled in the machine.

Positioning of the machine

The 4 hydraulic cylinders position the TERRA‐PIT DJ 18 in the working pit and adjust its inclination during surface launch. They can be adjusted to the front and rear, sidewise or downwards.

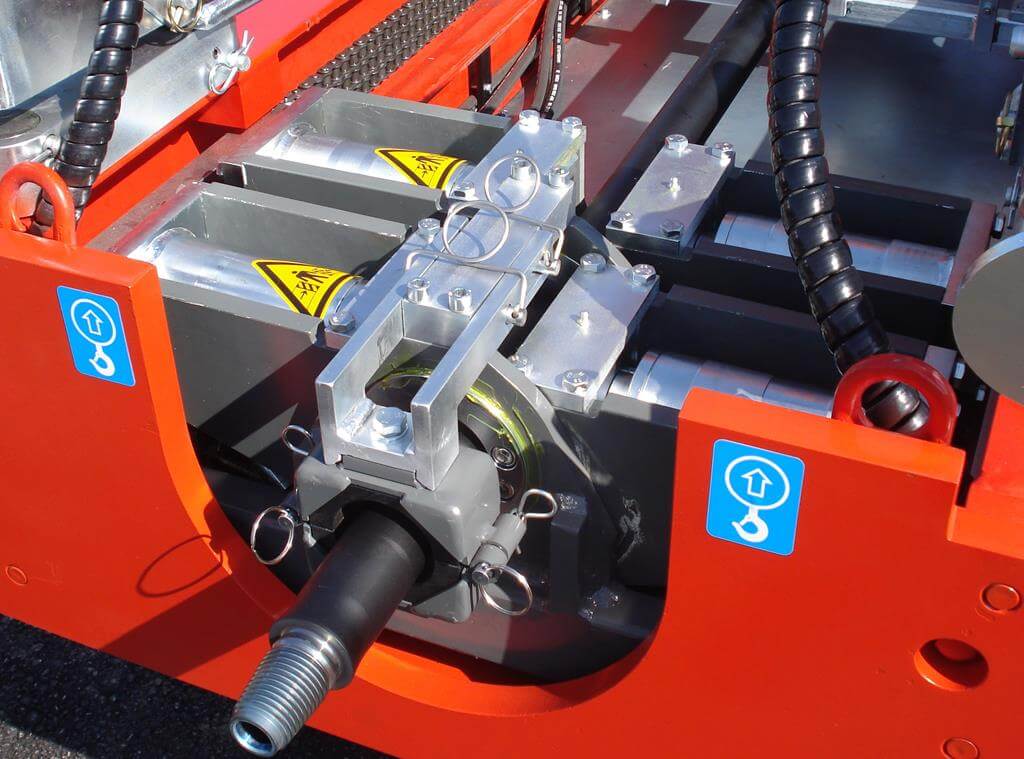

Hydraulic break apart system

The break‐apart‐system unscrews drill rods hydraulically. The clamping force is 11 tons, the break‐apart torque is 5.200 Nm.

Storage of the drill rods

At the machine 5 drill rods can be stored. The drill rods are made out of high quality steel. They have a bending radius of 24 m.

Clear control panel

All components of the TERRA-PIT are clearly arranged. The integrated electrical control of the the drilling volume takes place by the control panel. For the locating monitor there is a 12 voltage connection. The launching cradle is equipped with a grounding stake and an electrical strike alarm.

ADBS

The TERRA-PIT DJ 18 is equipped with a second generation Automatic Drilling and Backreaming System (ADBS).

This patented system automatically and within milliseconds adjusts the working speed of the drill to suite the ground conditions. In soft ground the drill operates at maximum speed, in hard ground slowly, but always at the optimum speed.

This allows the operator to operate the drill at maximum efficiency in a controlled and relaxed manner and prevents the drill rods and drilling tools from being overloaded. During the pilot bore the ADBS controls the thrust force. If the drill head hits an unexpected obstacle, the ADBS stops the drilling speed immediately and drills very slowly through the obstacle. All automatically!

Fluid Rock Drilling

The DJ 18 PIT can be equipped with a fluid rock drilling hammer. With this hammer even rock drilling or drilling in mixed ground conditions is no problem. The control panel has an optional integrated connection for the air compressor.

75 HP strong Hatz Diesel engine

The DJ 18 is equipped with a 75 HP strong HATZ Diesel engine. The engine speed can be adjusted between low and full speed. With two independent hydraulic circuits for thrust and rotation the operator can work with maximum pulling force and maximum spindle torque at the same time. The Power Pack can be lifted with a forklift or at the four yellow lifting eyes.

| Technical Data | |||

|---|---|---|---|

|

* Depending on ground conditions |

|||

| pullback force |

8 t (80 kN)

|

17’600 ft.lbs (9 US tons)

|

|

| thrust force |

8 t (80 kN)

|

17’600 ft.lbs (9 US tons)

|

|

| driving power |

55 kW (75 PS)

|

55 kW (75 HP)

|

|

| Torque |

3’000 Nm

|

1’920 ft.lbs

|

|

| drill rod rotation speed, 1st speed |

135 U/min @ 2000 Nm

|

135 rpm

|

|

| drill rod rotation speed, 2nd speed |

90 U/min @ 3000 Nm

|

90 rpm

|

|

| Drilling fluid volume, max. |

95 l/min

|

26 gpm

|

|

| Drilling fluid pressure, max. |

70 bar

|

1000 psi

|

|

| drilling speed – quick gear |

17.5 m/min

|

53 ft/min

|

|

| drilling speed – at full load |

8 m/min

|

20 ft/min

|

|

| pilot bore diameter |

ø 100 mm

|

ø 4″

|

|

| maximum backream diameter* |

ø 420 mm

|

ø 16.5″

|

|

| maximum drilling length * |

150 m

|

500 ft

|

|

| drill rods, length |

1.0 m

|

3.3 ft

|

|

| drill rods, diameter |

ø 57/54 mm

|

ø 2.3″ / 2.1″

|

|

| minimum turning radius** |

24 m

|

80 ft

|

|

| Dimensions pit cradle LxWxH |

2.0 x 0.90 x 1.25 m

|

6.6 x 3.0 x 4.1 ft

|

|

| dimensions hydraulic power pack LxWxH |

1.95 x 0.94 x 1.70 m

|

6.5 x 3.1 x 5.78 ft

|

|

| dimensions Mixing and Pumping Station LxWxH |

1.45 x 0.75 x 1.0 m

|

4.8 x 2.5 x 3.3 ft

|

|

| weight of the pit cradle |

1’300 kg

|

2’860 lbs

|

|

| weight of hydraulic power pack |

1030 kg

|

2260 lbs

|

|

| weight of Mixing and Pumping Station |

205 kg

|

451 lbs

|

|

Kontakty

Vedúci divízie cestnej mechanizácie

Ing. Otokar Macháček

Technické poradenstvo Dynapac a Terra

Diagnostický technik

Tel. kontakt: +421 948 332 182

Email: otokar.machacek@jamalsk.sk

Náhradné diely

Jakub Mihalik

Technické poradenstvo

Tel. kontakt: +421 903 721 664

Email: jamalsk@jamalsk.sk